Centritec Seals offer superior performance and critical benefits in lifespan, efficiency and cost when compared to other seal types. While there are multiple types of non-contact seals available in the marketplace, with its unique, patented design, Centritec Seals has proven to be one of the most efficient, shaft seals for both horizontal and vertical applications.

Rather than locking in fluid using internal pressure, like a centrifugal seal, a labyrinth seal by design will have some amount of leakage. Labyrinth seals must be produced with a "route" for the leaking lubricant to follow. This typically results in a complex, indirect path in the seal's internal labyrinth path through which the lubricant flows. This channel can allow contamination to enter the seal, as it is "open" to external conditions.

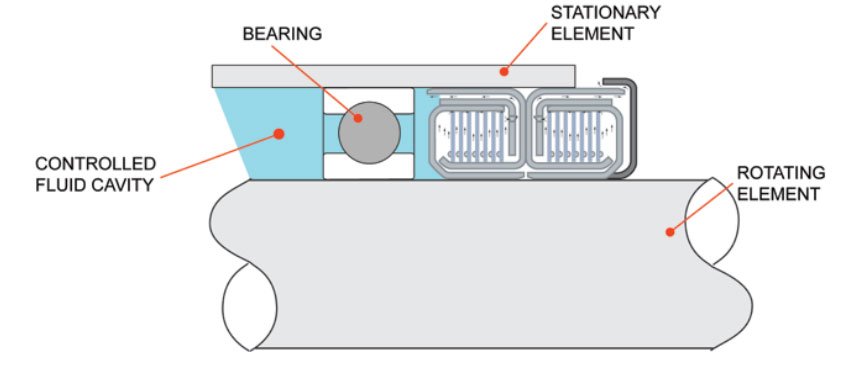

In comparison, a Centritec Seal's centrifugal operation locks lubricant in and requires no expulsion of fluids. This ensures that sufficient amounts of lubricant are maintained, and that lubricant quality is not compromised by dirt, water or other contaminants. Centritec Seals also prevent lubricant from leaking out of the controlled fluid cavity between stationary and non-stationary elements.

The rotating chamber in a Centritec Seal significantly reduces operational speed requirements compared to other typical non-contact seals, though it will also operate at extremely high speeds. This patented design makes Centritec Seals ideal for a wide array of applications, and allows the use of very low viscosity fluids.

The rotating chamber within a Centritec Seal develops internal pressures that pump lubricant back into the controlled fluid cavity. This allows for greater tolerance of axial movement and vibration, and provides flexibility in the seal's positioning. Most standard non-contact seals, such as a labyrinth seal, have strict dimensional requirements. If alignment is changed slightly the seal can fail, lubricant can leak and an entire system can be compromised. Ensuring proper axial alignment can become a time-consuming maintenance effort that results in increased costs and downtime. Centritec Seals effectively solve this issue.

With the seal's non-contact design and internal pressure sealing method, Centritec Seals operate with much greater efficiency than mechanical shaft seals and other non-contact seals, such as labyrinth seals. There is little rotational fluid shearing and hence less friction to overcome. This significantly reduces the possibility of friction-induced overheating.

Centritec Seals have proven to be the most effective option for an array of drive shaft sealing applications. When other shaft seals fail, Centritec Seals hold up against extreme conditions, providing the most reliable sealing solution.

Contact Centritec Seals for more information on our non-contact seals, or to request a quote for your application.

Operating Parameters |

Centritec Seal |

Labyrinth/Bearing Isolator |

Sealing Method |

Centrifugal Pressure |

Labyrinth with "O"Ring |

Degree of Contact |

100% Non-Contact |

"O" ring contact |

Speed |

Up to 50,000 rpm |

10,000 rpm |

Friction |

Zero |

Some at startup/shutdown & slow speed operation |

Contaminant Ingress |

Minimal at rest then pumps out |

Some, no pumping action |

Lubricants |

Oils, greases, water, gases |

Oil, grease |

Operating Pressures |

Speed dependent with 0 to 50 psi |

0 psi |

Lubrication Flow |

Laminar |

Turbulent (splashing occurs) |

Vibration |

Completely tolerant |

Minimum tolerance |

Alignment |

Non-dependent |

0.005" axial - 0.015" radial |

Orientation |

Horizontal or vertical |

Horizontal or vertical but with 0 psi pressure |

Heat Buildup |

Self-venting & Purging |

Not self-venting or purging |

Temperature Range |

-35°F to 650°F |

-35°F to 400°F |

Installation |

No special tooling |

Precise alignment needed |