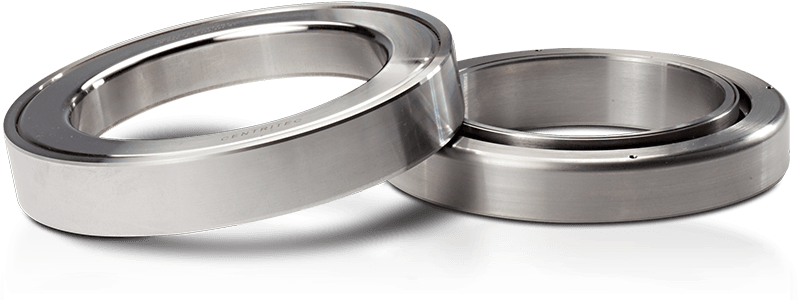

At Centritec Seals we are proud to manufacture one of the industry's most innovative and reliable sealing components. Our unique centrifugal design solves problems in performance-critical systems, providing flexible mechanical seal solutions that require less maintenance, reduce downtime and increase lifespan.

A Division of Carlyle Johnson, the Centritec Seals team has decades of experience in the design and manufacture of industrial components, including system integration and customization based on application. Our manufacturing facility is equipped with advanced production and inspection equipment, which allows us to efficiently manufacture seal components with precision and accuracy.

Centritec Seals are highly-efficient, and utilize a rotating chamber sealing method that significantly reduces operational speed requirements compared to typical non-contact sealing alternatives. Our centrifugal seals utilize their own inherent pumping capability to generate pressure and form a no-leak "barrier" that prevents contamination and reduces downtime and maintenance. With a wide array of features and benefits, Centritec Seals has become recognized as one of the industry's leading manufacturers of mechanical seal solutions.

Where other shaft seals fail, Centritec Seals are able to provide reliable operation – even in installations with extreme operating conditions. From dirty environments to very high and very low temperature applications, Centritec Seals keep systems up and running. Our seals are used in a variety of applications, and can be customized to meet your specific requirements.

Whether you are creating new equipment or upgrading seals to enhance efficiency and cut down on maintenance expense for older machinery, our engineers offer tailored mechanical seal solutions to meet your needs.

Contact Centritec Seals for more information on our non-contact seal manufacturer services, or to request a quote for your application.